Authors: Yvonne A. Akomea, Tatiana Beliaeva, Achwak Ben Abdessalem

Advanced materials need from industries

With a rising orientation of businesses and governments towards sustainability and green transition, companies in the transportation, construction, manufacturing, and energy industries are increasingly searching to integrate sustainable materials into their production processes to lessen their carbon footprint. They are searching for sustainable alternatives, which are also functional, fashionable, and cost-effective. These transformations in various industries drive the demand for new materials.

According to the projections from the World Bank, the demand for critical raw materials is expected to increase by about 500% by 2050.

In response to the current market trends, emerging technologies and innovations are being developed in the materials industry, which range from nanomaterials and advanced materials with enhanced properties to the adoption of AI and a data-driven approach to accelerate the exploration and modeling of matters.

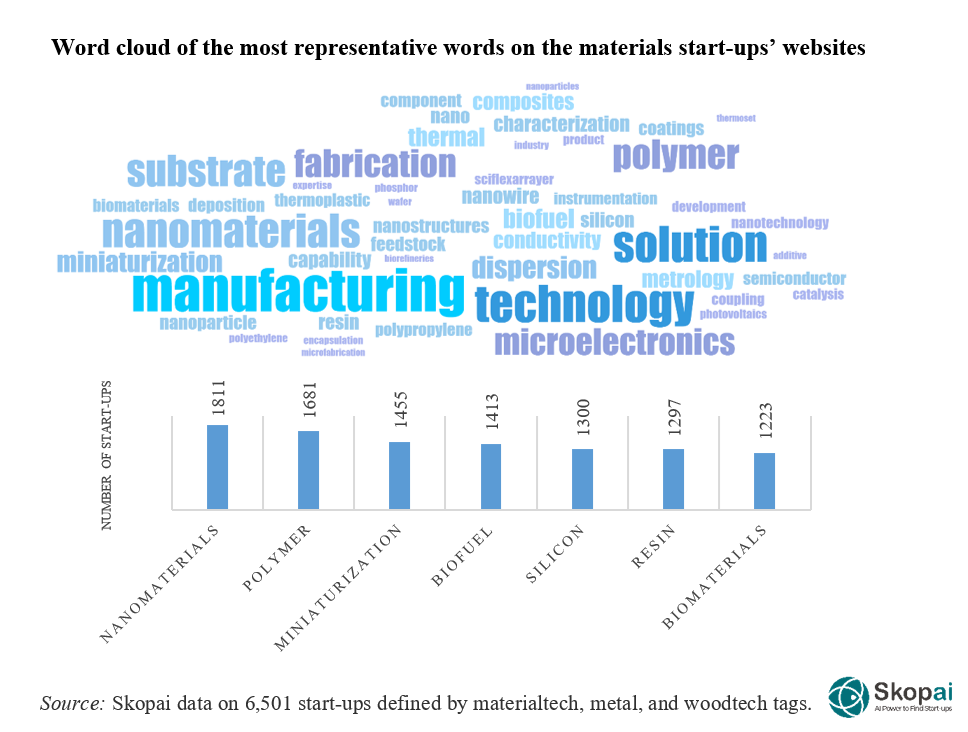

The analytics based on 6,501 materials start-ups shows the most frequently used words on their websites. For example, materials and technologies such as nanomaterials (appear in 28% of start-ups), polymer (26% of start-ups), miniaturization and biofuel (22% of start-ups each), silicon and resin (20% of start-ups each), and biomaterials (19% of start-ups) are among the dominant words start-ups use on their websites. According to the data, this start-ups have filed 886 patents and raised 4 billion euros from investors in 2021.

The development of new materials spans various critical subsectors such as chemicals, metal, and wood, and the emerging innovations which are discussed below.

Next-generation materials in chemical, metal, and wood industries

Chemicals

According to the World Economic Forum, climate stabilization requires full decarbonization of our energy systems. Plans to reduce carbon emissions to comply with commitments were adopted in 2015 under the Paris Agreement on Climate Change. The EU plans to reach net-zero emissions by 2050 and aims to reduce emissions by half in the next decade. This strong commitment imposes especially stringent requirements on the chemical industry because it represents a large share of global emissions. It is a power-consuming industry that depends on hydrocarbons for its raw materials. So reducing these emissions will require a huge investment for States, companies, and start-ups. As highlighted by the International Energy Agency (IEA), technologies to achieve 75 % of the required emissions reductions by 2050 are not commercially available today.

But these challenges also provide a particularly powerful set of opportunities for the chemical industry to position itself as a key partner in the transformation towards the sustainability of its customers’ industries. As key participants in the manufacturing value chain, chemical companies that are rapidly preparing to meet more stringent environmental, social and governance (ESG) standards will be an advantage. And their reaction to ESG problems will spur innovation. There is an increasing number of technological start-ups in the field of chemistry that propose innovative solutions to help achieve this goal by 2050.

As key participants in the manufacturing value chain, chemical companies that are rapidly preparing to meet more stringent environmental, social and governance (ESG) standards will be an advantage.

For example, a French start- up AFYREN is offering a bio-based replacement for petroleum molecules to a wide range of industries. Its technology uses natural microorganisms found in food flavors, mold inhibitors, cosmetics, lubricants used in plane and refrigerator motors, household cleaners, additives in animal feed, and more in order to replace carboxylic acids made from petroleum.

Checkerspot is another example of start-up which was founded in 2016 in the US. It designs and manufactures high-performance biomaterials. The start-up’sWING platform engineers microalgae-based matters at the molecular level. It also creates high performance ingredients and substances while at the same time reducing waste and greenhouse gas emissions, driving towards a post petroleum future. In August 2020, the company raised $36M in a Series B funding round. It intends to use the capital for commercial development and the expansion of its product and innovation platform.

Access the list of green chemistry start-ups for more information (link available until August 1, 2022, or contact@skopai.com):

Metal

The metal and mining industry is an important economic sector that contributes massively to employment and public revenue although it is also one sector that contributes majorly to environmental degradation. Industrial activities over the last century have caused depletion of natural resources and massive environmental pollution affecting the quality of air, water, and land. Mercury, arsenic, lead, chromium, and cadmium have been the most common heavy metals to have induced human poisonings leading to cancer and respiratory problems.

Metallurgical sectors are on a quest to improve product quality and enhance the efficiency of materials utilization while reducing energy consumption and mitigating fossil CO2 emissions.

As metals and minerals are important raw materials needed in society, their production is extremely critical to the transition to a sustainable net-zero economy. New sustainable technologies such as electric vehicles (EV), batteries, wind power, and solar energy all require metals in their production. Metal and mining companies are tasked to incorporate low emissions technologies into their operations to mine sustainably. The importance of green metallurgy cannot be overemphasized. Metallurgical sectors are on a quest to improve product quality and enhance the efficiency of ressources utilization while reducing energy consumption and mitigating fossil CO2 emissions. Utilization of renewable and green biocarbon energy and clean energy sources such as hydrogen are under development to secure the sustainability of this vital sector, but also for the efficient recovery of metals and residue recirculation, which are essential to sustain zero waste valorization of metallic residues. Also, companies are transitioning from the use of heavy metals to light metals such as lithium and cobalt for batteries, copper for electrification and nickel for EV batteries and tellurium for solar panels.

Some start-ups have been developing innovative solutions to contribute to a sustainable metallurgy process. For example, a French start-up Vulkam is specialized in the manufacture of components in Amorphous Metallic Alloys called Vulkalloys. It uses a patented process of moulding amorphous metals to create metallic pieces and micro pieces. It has developed a total of eight alloys based on Zirconium, Copper, Nickel, or Hafnium. These Vulkalloy components are used in many fields such as watchmaking industry, the aerospace & defense industry, and the medical industry.

Discover more metallurgy start-ups (link available until August 1, 2022, or contact@skopai.com):

Wood

Actions towards wood production can be sensitive as it boils down to the felling of trees which if not controlled can lead to deforestation. With the ubiquity of wood products in our lives, sustainable forestry and sustainable wood production are crucial not only to achieving a green economy but more importantly because trees are vital to life on earth and act as an important buffer against climate change. Hence to properly achieve both environmental and production goals, society needs to address actions such as proper tree felling so as not to cause erosion, as well as proper forest management and stringent laws to prevent illegal forest activities. Human activities such as campfires left unchecked, negligently discarded cigarettes, intentional acts of arson etc. that can lead to wildfires can be avoided.

Forests and log production are at the heart of the EU Green Deal which aims to protect and restore forests. In the EU Forest Strategy for 2030, the Commission aims to promote the import of products not involving deforestation, drive the demand for sustainable forest management practices encompassing biodiversity protection across Europe, and support the restoration of degraded forest ecosystems. The strategy also sets a roadmap for planting billion additional trees across Europe by 2030 abiding by all ecological principles.

In the EU Forest Strategy for 2030, the Commission aims to promote the import of products not involving deforestation, drive the demand for sustainable forest management practices encompassing biodiversity protection across Europe, and support the restoration of degraded forest ecosystems.

The construction, furniture, and packaging industries all use wood in their work. Many start-ups in these sectors are developing products and processes for a sustainable future. For example, a Chilean start-up Strong by Form develops sustainable ultralight high-performance timber-based biocomposites able to replace steel, aluminum and concrete in construction and mobility.

Daika, a start-up founded in 2020 in Israel, develops a new matter composed from natural materials and wood waste. The resulting products retain the unique properties of wood such as warmth, sense, and acoustics and can be processed as regular wood.

Nature Coatings is an American start-up developing solutions designed for transforming wood waste into high performing black pigments suitable for multiple applications such as printing, coatings, paint, or wood coloring.

Learn more about wood processing start-ups (link available until August 1, 2022, or contact@skopai.com):

Other factors reshaping materials industry

The current changes and innovations in the materials are driven to a large extent by sustainability considerations across industries. These trends have promoted the development of multiple solutions in chemicals, metal, and wood sectors to respond to major industrial challenges and accelerate green transition.

Besides that, other factors and technological advances are reshaping the industry such as digitalization and evolving industry 4.0 technologies. For example, the advances in AI and ML allow processing large amounts of complex matters data in a meticulous and rapid manner, which makes it possible to accelerate research and development and deliver novel scientific insights in the field. Furthermore, digital technologies are increasingly involved into materials management and operations, such as digital platforms or robotic manipulations allowing higher degree of autonomy in mining or fabrication processes. Overall, next-generation innovations in the materials industry are expected to contribute to the upcoming industrial breakthroughs since the latter commonly go hand-in-hand with the development of new materials.

AUTHORS

Yvonne A. Akomea

Marketing Manager

Achwak Ben Abdessalem

Sales Analyst

Tatiana Beliaeva

Senior Entrepreneurship Researcher